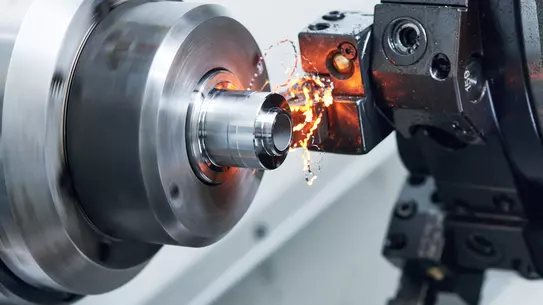

Principle

The HITSERT® 2 thread insert is heated to the melting temperature of the plastic. As a result of the heat transfer upon insertion, the plastic is plasticised for a short time and flows into the undercut of the thread insert. As the plastic cools, it creates a tight fit with low stress.

Advantages

- Ideal for thermoplastic materials

- Specially designed for thermal installation

- Screw-locked and low-tension anchoring

- High pull-out values

- Efficient installation with single-mandrel, multi-mandrel and automated insertion machinery with preheating device