Benefit from the new key facts

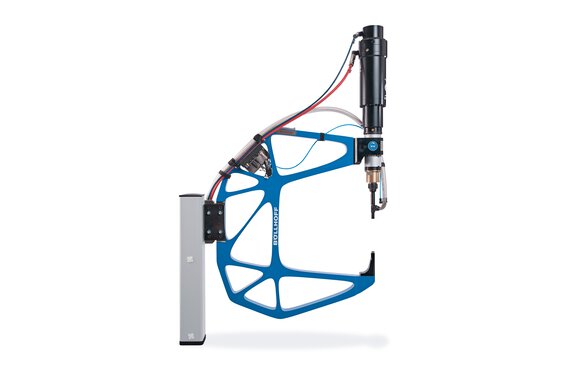

- Modular electrical lightweight system

- High joint quality and a wide application range due to

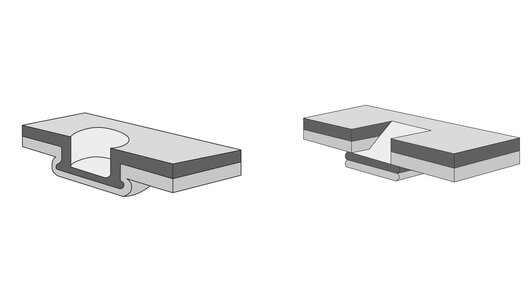

- dies with spring segments

- path-controlled process with adjustable residence times that allows maximum undercut values

- Low-maintenance drive with 67 kN total force

- Compact, robust and reduced-weight with C-Frame Select

- Modular design with mechanical strippers and punches in various sizes for different joining forces

- One supply unit for different joining technologies – self-pierce riveting and clinching

- Flexible due to quick and easy retooling to vary between the RIVSET® and RIVCLINCH® technology

- Wide application range (aluminium – steel – stainless steel)