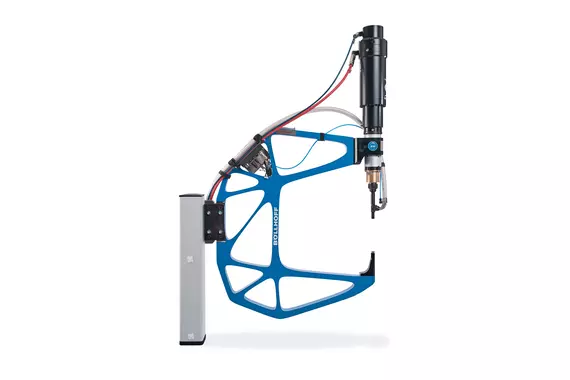

RIVSET® self-pierce rivets differ in terms of material, head and shaft geometry, hardness, surface, shaft length and diameter.

Special features of RIVSET® self-pierce rivets

- High-strength joints

- Reproducible joining results

- No pre-punching

- Liquid-tight and gas-tight

- Suitable for different types of materials

- Suitable for various material thicknesses and strengths

- Can be used for hybrid joints (in combination with adhesive)