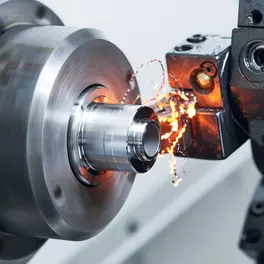

Custom-made drawing parts of metal

Custom-made parts and special products

We develop and manufacture custom parts based on your individual requirements.

For custom requirements

High-quality fasteners: developed and manufactured to customer specifications

We specialise in the production and procurement of custom‑made parts. We consider the materials, manufacturing processes and surface finishes required to offer you the best solution for your application from both a technical and cost perspective. Quality is our top priority.

Plus factors

Advantages of our custom-made parts

Unlimited range

We manufacture fasteners in all dimensions, lengths, diameters and batch sizes – individually assembled, labelled and packaged on request.

Fast development process and delivery

Take advantage of our expertise and professional development work. We produce prototypes and samples in‑house.

Comprehensive support

We support you from the design stage through to the creation of prototypes and serial production.

Modern technology

We are always on the cutting edge of technology and are familiar with the latest legal requirements.

Reduce costs

We improve your products and lower your production costs.

High quality

We ensure the quality of our products in our accredited testing lab.

From A to Z

Order custom-made parts

Take advantage of our experience

Our custom-made products: as diverse as your requirements

Our services at a glance

- Manufacturing processes: turning, CNC milling, cold-forming, hot-forming, punching and combined punching and bending, pressing

- Materials: machining steel, cementation and heat-treatable steel, rust and acid-resistant steel, heat-resistant materials, nickel, titanium, bronze, copper, brass, aluminium alloys, plastic, special materials

- Surface treatments: galvanising, nickel‑plating, chrome‑plating, bronzing, burnishing, phosphating, anodising, zinc‑coating, organic coating, powder coating, seal coating, locking coating, adhesive coating, chromium(VI)‑free coating, friction value adjustments

- Repairs/reworking: grinding, milling, honing, lapping, cutting threads, rolling threads, barrel finishing, sandblasting, hardening, heat treating, mounting, pressing

WE ARE HAPPY TO HELP

Do you have any questions or a current project?

Let us know – we will get in touch with you.

Contact us