- For machining materials with a strength rating up to 700 N/mm2.

- Only suitable for blind holes if sufficient tapping space is present.

- Minimum requirement is 1d deeper that the fully cut-out thread length.

Thread-forming in metal

HELICOIL®

There are plenty of options, from simple manual installation tools to standard tools to fully automated complete systems.

Thread-forming in metal

Creating high-strength fastenings

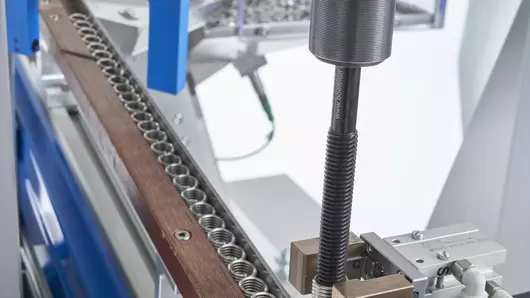

Our assembly solutions are designed as fully automatic or semi-automatic workstations. Depending on your requirements, parts can be handled by the operator, a handling system, a rotary indexing system or a transfer system. Take a look at our assembly solutions.

Method and principle

The HELICOIL® installation process

HELICOIL® thread inserts create high-strength, wear-resistant, heat-resistant thread of the highest precision by transferring the forces from flank to flank into the pilot thread. The reduced diameter of the HELICOIL® Plus in the first turn ensures that the thread insert can be installed like a screw.

Installing HELICOIL® thread inserts is easy and cost-effective, because there are only a few basic rules to follow. For efficient assembly, whether for a single application or for high-volume production, we provide a broad range of manual and automated installation tools.

The HELICOIL® system combines conformance to standards with easy installation.

The installation steps in detail

Core hole drilling

You can use a standard twist drill.

Use a 90° cutter for countersinking and deburring before thread cutting. External diameter of the countersink = DHC + 0.1 mm.

Thread cutting

You should use our system’s original HELICOIL® taps to cut the HELICOIL® Plus pilot thread. Use HELICOIL® plug gauges to verify that pilot thread is true-to-gauge.

Thread forming

Use a thread former to quickly and easily produce a chipless internal thread.

Thread installation

You can carry out the installation with a manual installation tool, an automatic installation tool or a fully automated solution.

Interested?

Order HELICOIL® thread inserts online now

In the eShop, you will find the latest information on price and availability, technical data sheets and CAD downloads, as well as our varied range of branded products and standard parts.

Visit eShopAutomation

HELICOIL® Automatic installation tools

Cost-effective installation of HELICOIL® thread inserts is just as important as their high quality standard. Our range includes modules for integration into automatic processes and complete systems.

Do you have specific requirements? If so, please contact us!

Videos

The HELICOIL® technology

Information and more

Downloads

Are you interested in HELICOIL®? Please download further information here.

- HELICOIL® PlusThread technology for high-strength fastenings (metric threads)pdf9 MBen

- HELICOIL® SmartThe new generation of thread technology for high-strength jointspdf3 MBen

- HELICOIL® TangfreeThe tangfree coil thread insert for high-strength threadspdf3 MBen

- HELICOIL® AutomationSystem solutions in thread technologypdf3 MBen

- HELICOIL® E-PSG 256 Quick ExchangeQuick and process-reliable switch of different dimensionspdf211 KBen

- HELICOIL® E-PSG 256 Electrical screwdriverHigh process reliability and reduced assembly timepdf188 KBen

- E-PSG and ES-410Electrical installation tool for HELICOIL® thread insertspdf335 KBen

- HELICOIL® E-PSG Process ControlledFast installation of HELICOIL® thread inserts with high process reliabilitypdf497 KBen

Any questions?

We are here to assist you

Do you want to know more about our products or services? Our team will be happy to advise you.

Contact us