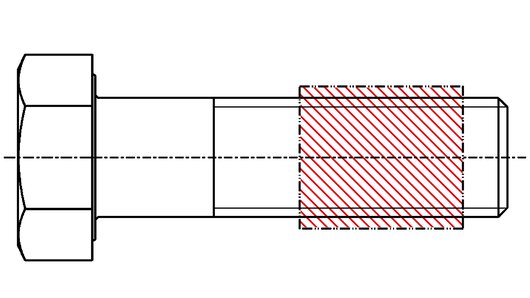

Bonding bolt and nut threads together is a reliable way to prevent them from working loose. With this method, the applied microcapsules are destroyed by the pressure exerted when the connection is screwed together. The adhesive contained in the capsules then combines with a hardener. This results in a chemical reaction (polymerisation), which causes the adhesive to harden (adhesive bonding) and produces the desired locking effect. The locking effect is achieved by bonding the bolt and nut thread. The pre-tensioning force applied here is largely preserved (anti-rotation lock).

Product types

- Precote 30

- Precote 80

- Precote 80-3

- Precote 85

- 3M Scotch Grip 2353

- 3M Scotch Grip