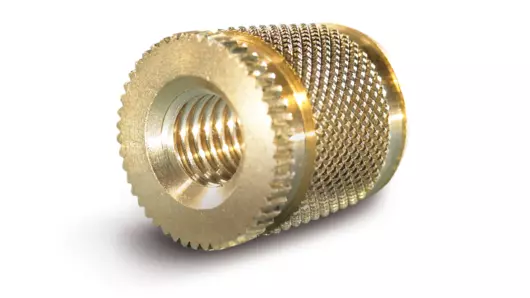

High-strength thread inserts for plastic parts

AMTEC® stands for "After Moulding TEChnology"

This term refers to the installation of brass thread inserts in plastic components after moulding.

Plus factors

Advantages of AMTEC®

Shorter injection cycles

No wasted time. Injection moulding takes place automatically and without inserting metal parts.

No damage to the injection mould

Reliable manufacturing. No metal parts that could fall out.

Secure, low-stress anchoring

High pull-out and torsion values. Because the plastic is heated during installation, as it cools, it creates a tight fit with low stress.

Method and principle

High-strength and wear-free threads

Today, it is impossible to imagine the world of lightweight construction without plastics, and they are conquering ever more sectors. Their great flexibility in terms of processing and component design leads to an increasing replacement of metallic materials by plastics. With their outstanding mechanical properties, low weight and attractive manufacturing costs, plastics are a fundamental part of industry today.

AMTEC® is the name of the thread inserts and assembly systems that we provide for after moulding technology. These thread inserts have been designed specifically for after moulding installation. The result: a wear-free, high-strength thread for your high-quality plastic components.

Any questions?

We are here to assist you

Want to know more about our products or services? Our team will be happy to advise you.

Contact usFIND THE RIGHT SOLUTION FOR YOUR APPLICATION

AMTEC® Installation procedure

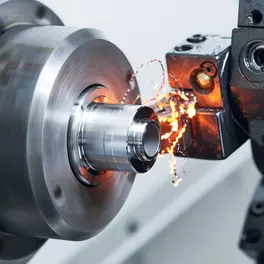

We offer a wide range of thermal installation machines as well as manual and semi‑automatic installation tools.

Heat element welding (HEW)

Heat element welding is a tried and tested joining technique for embedding metal thread inserts into thermoplastic mouldings. During the single-phase process, contact heat is transferred to the joining zone of the plastic via the metal insert. As the surface of the plastic melts where it makes contact with the metal insert, the plasticised mass is forced into specific recessed areas and undercuts to produce a form-fitting joint.

Suitable for

- HITSERT® 2

- HITSERT® 3

- SONICSERT®

Electromagnetic resistance welding (ERW)

ERW (electromagnetic resistance welding) is a technique developed by KVT Bielefeld GmbH for joining metal and thermoplastics. An electromagnetic AC field heats the thread insert without touching it, and the surface of the plastic component is plasticised where the insert makes contact with it. At the same time, the melted material is forced into depressions and undercuts and the materials are joined together.

Regardless of their size, the metallic elements heat up within a very short time (approx. 2–6 seconds). After the power supply is switched off, accelerated cooling of the melted material takes place, allowing an installation accuracy of up to 0.05 mm.

Suitable for

- HITSERT® 2

- HITSERT® 3

- SONICSERT®

Ultrasonic welding (USW)

USW is a process that was originally developed for joining thermoplastic parts. It creates friction between the parts to be joined and causes them to absorb vibrations, with the result that the plastic material is plasticised within a very short time. The joining process then takes place. The necessary energy is generated as alternating voltage in the ultrasonic generator, converted into mechanical vibration (20 – 40 kHz) and then introduced with a sonotrode. When the thread inserts (metallic M2 – M6) are embedded in the thermoplastic material, the melted material is forced into recessed areas and undercuts.

Suitable for

- SONICSERT®

Expansion anchoring

When the thread insert is inserted into the mounting hole, the diamond knurling is expanded by the spreader plate, which is pushed down. The knurling then anchors itself in the wall of the hole.

Suitable for

- EXPANSIONSERT 1

- EXPANSIONSERT 2

- SPREDSERT® 1

- SPREDSERT® 2

- SPREDSERT® with retaining flange

- QUICKSERT® Expansion (type 1230)

Self-tapping insertion

The thread bush is screwed in with a rotating spindle.

Suitable for

- QUICKSERT®

- QUICKSERT® Hex

- QUICKSERT® Plus

Interested?

Order AMTEC® thread inserts online now

In the eShop, you will find the latest information on price and availability, technical data sheets and CAD downloads, as well as our varied range of branded products and standard parts.

Visit eShopVideos

AMTEC® technology

Information and more

Downloads

Interested in AMTEC®? Please download further information here.

WE ARE HAPPY TO HELP

Do you have any questions or a current project?

Let us know – we will get in touch with you.

Contact us