Services

Accredited test laboratory

Whenever you require independent testing of connections and fasteners, you can make use of our laboratory service.

Accredited and independent in accordance with DIN EN ISO/IEC 17025:2018

The test procedures at our physical‑technical test laboratory are accredited in accordance with DIN EN ISO/IEC 17025:2018 guidelines. The accreditation applies to the procedures listed in the annex to the accreditation certificate. When faced with particularly complex and unusual challenges, our customers benefit from our close cooperation with colleges, universities and the Fraunhofer institutes.

Your advantages in product development

- Quick comprehension of the task at hand

- Precise development of the appropriate fastening solution

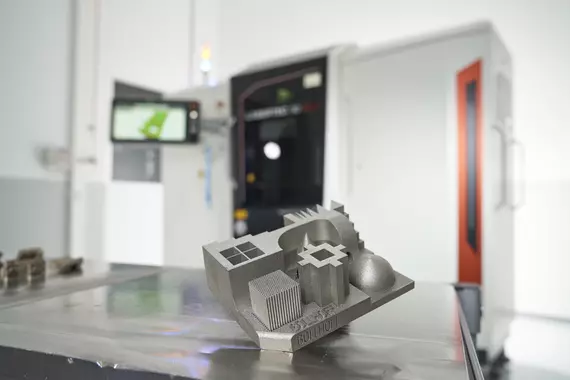

- Production of prototypes using the laboratory's own prototype construction processes

- Verification of the solution by determining the mechanical and physical values

- Inclusion of practice-related conditions in the test

- Documentation of the results in accordance with applicable standards

»"We test components made from a wide variety of materials with numerous test methods: from mechanical-technological tests to corrosion tests to damage analysis. It doesn’t matter whether it is a Böllhoff product or a product from another manufacturer."

The Big Five

The professional competence and the technical equipment of our test laboratory are assessed regularly on-site by the national accreditation body of the Federal Republic of Germany (Deutsche Akkreditierungsstelle – DAkkS). This guarantees independence and impartiality towards third parties and our test reports are recognised worldwide. The accreditation applies to the procedures listed in the annex to the accreditation certificate.

Specifically, the Böllhoff test laboratory is accredited according to DIN EN ISO/IEC 17025:2018 for the following five areas that we call The Big Five:

1 Mechanical-technological testing

Mechanical-technological testing consists of test procedures that determine the behaviour and material parameters of standardised material samples or finished components under mechanical stress. Unlike physical values, technical properties depend on the boundary conditions under which they are tested. For this reason, such procedures are often standardised to ensure that test results can be compared. The Böllhoff laboratory is equipped to test fasteners in a wide range of dimensions and materials.

2 Metallographic tests

Metallographic tests provide qualitative and quantitative descriptions of the structure of metallic materials using microscopic methods. The metallography consists of preparation, structural display and/or description, and structural assessment. Errors during these steps can lead to an incorrect assessment of the structure. The employees at the Böllhoff laboratory are specially trained and familiar with the typical materials used in fasteners and common coating materials.

3 Surface and dimensional testing of fasteners made of metallic materials

Surface and dimensional tests on fasteners provide information on the condition of the uncoated surface of a fastener (e.g. regarding freedom from surface defects and the roughness of the surface). They include testing geometric dimensions in coated and uncoated state (e.g. flank and core diameters of screws), and determining the thickness of the coating which is usually applied to provide corrosion protection. The Böllhoff laboratory is one of only a few laboratories accredited for testing surface defects (cracks, overrolling).

4 Testing of low and high alloy steels using optical spark emission spectrometry

The chemical composition of a metallic material can be determined with relative precision using optical spark emission spectrometry. The test result goes beyond a pure PMI (positive material identification) test. Precise knowledge of the alloy and trace element contents is important, as even the smallest fluctuations can have a significant influence on the properties of the component. The Böllhoff laboratory specialises in testing small dimensions.

5 Corrosion test

The salt spray test is a recognised technical procedure for testing the corrosion resistance of fastener coatings – with the goal of monitoring the quality of the coating process and the coated components. The Böllhoff laboratory can also offer this test in combination with the climate change test. To characterise the bimetallic corrosion tendency (contact corrosion) of joints, the Böllhoff laboratory uses a short-term testing procedure with potential measurements.

Böllhoff technical seminars

Take advantage of our expertise

As part of the Böllhoff Academy, the physical-technical laboratory provides training for Böllhoff employees and specialist seminars for external users. Our technical seminars include interesting presentations by experienced speakers, covering new developments and approaches, as well as many practical examples. This training programme provides excellent knowledge transfer in a professional environment and enables participants to ask targeted questions.

Learn more now

Would you like to find out more about our accredited test laboratory or are you interested in our seminars?

Contact usGallery

Downloads

Laboratory brochure

This brochure provides details on the competencies and services of our accredited test laboratory.

Certificates

Standards

Standards according to which the physical-technical laboratory of the Böllhoff Group is accredited and which are approved for flexibility.