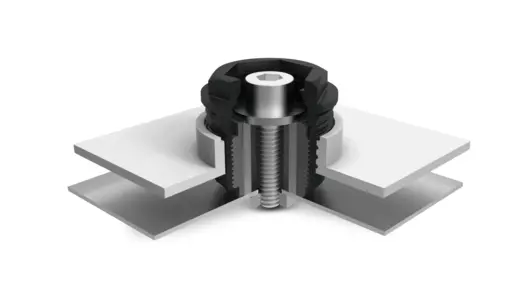

This two-piece system is made entirely of metal and can therefore withstand high loads.

The minimal space required for installation in the separation gap makes this solution easy to install – and even retrofit – in an existing installation space. With the new generation of the FLEXITOL® Metal adjustment element, the system is significantly more durable and can furthermore be manufactured in a more cost-effective process.

Adjustment element

- For this new generation, the integrated friction function was transferred to the adjustment element interior.

- High-strength metal thread

Fastening element

- Compact system dimensions

- Blind rivet nut available in various versions

- Easy installation through established blind riveting technology