Direct fastening

QUICK FLOW® Plus

Thin sheet metal screw

Securely joining thin sheets: Achieve optimum results with QUICK FLOW® Plus screw.

For secure direct fastening

With QUICK FLOW® Plus you can join sheet metal without a pilot hole – stable, secure, reusable

Böllhoff is your expert for innovative joining technology. Our QUICK FLOW® Plus screws provide an outstanding solution for joining sheet metal and thin-walled components – without pre-drilling and nut elements. Components are becoming increasingly lighter in their construction to enable sustainable production and technological advantages. When it comes to design and technical implementation in construction and assembly, however, lightweight construction poses a number of challenges. QUICK FLOW® Plus fasteners are thread-forming screws that are specially designed for use with thin sheets and thin-walled components and offer technological advantages. They represent a cost-effective alternative that saves on nut elements and manufacturing costs. Find out how our thread-grooving fasteners optimise your processes and make joint connections durable and secure.

Fastening sheet metal without nuts – safe and durable

When joining thin sheets with classic sheet metal screws with ST threads, it is often necessary to use nut elements. Direct fastening with QUICK FLOW® Plus is more benefical for the lightweight construction methods used in many industries today, as it enables secure and long-lasting fastening without additional components such as nuts. You save on weight, time and costs, and benefit from increased process reliability.

Enjoy the advantages of our QUICK FLOW® Plus self-tapping screws. The fasteners are screwed into the thin sheet without a pilot hole and without prior thread cutting. This method ensures fast and cost-effective fastening, for example in the assembly of ventilation systems, household appliances and electronic housings, as well as the fastening of components in the automotive industry.

Plus factors

The advantages of QUICK FLOW® Plus screws

Process optimisation

Economical: With QUICK FLOW® Plus, there is no need for pre-drilling or punching as well as thread cutting. The screw tip penetrates the metal, forming its own rim hole. Benefit from the time savings and the reduction in process costs.

Automation

Quick and reliable: Automated installation of QUICK FLOW® Plus fasteners is possible.

Thread-grooving instead of thread-cutting

The advantage of thread grooving is that no chips are produced and the work hardening creates a stronger female thread.

Application oriented

Our QUICK FLOW® Plus screws are available in various sizes and dimensions. Since single-side access is all that is needed to use the fasteners, they are guaranteed to find many practical applications.

Flexible assembly

Components can be positioned as desired, as there is no need for pre-drilled holes. There are therefore no problems with production-specific tolerances.

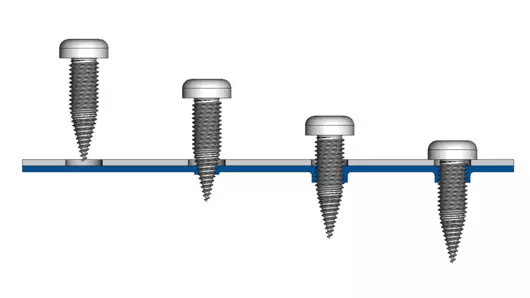

The easy method for fastening sheet metal

Operating principle of QUICK FLOW® Plus fasteners from Böllhoff

The QUICK FLOW® Plus thin sheet metal screw is a self-tapping fastener that has been specially developed for use with thin-walled sheets and thin-walled components. Time-consuming process steps such as cutting a thread, generating a core hole or cleaning are no longer necessary with this fastener. Self-tapping screws are thread grooving fasteners that generate their own female thread. This means that the female thread created in the sheet metal is grooved and is not cutted. Thread-grooving instead of thread cutting offers two major advantages: greater strength in the female thread thanks to work hardening resulting from the grooving process and no annoying chips.

The female thread is created with the forming zone of the screw. The prerequisites are that the screw thread must be stronger than the workpiece and the workpiece must be sufficiently ductile. The generated rim hole ensures that the created female thread is at a more favourable installation height at the joint. The thread pitch is finer than that of conventional self-tapping screws, ensuring sufficient overlap of the formed thread flanks. The use of additional nut elements is therefore not necessary. QUICK FLOW® Plus thin sheet fasteners also have a double-start thread. This results in shorter cycle and process times. To optimise the joining process, bits are included that prevent the screw from tumbling due to their special geometry. This makes the fastening process convenient for the worker, even in difficult assembly situations.

QUICK FLOW® Plus thin sheet fastener

Your questions about QUICK FLOW® Plus

Thread-grooving fasteners create a female thread when screwed into the workpiece and thus create a stable joint without the need to pre-drill or punch and cut a thread.

Thread-cutting screws cut their own female thread as they are screwed in. This creates chips. Chips do not occur when thread-grooving, as grooving does reshape the component material instead of cutting it. Reshaping the metal workpiece in a cold state also generates threads with a higher strength due to work hardening.

Yes, QUICK FLOW® Plus fasteners can also be installed using a standard rechargeable driller. We strongly recommend using the supplied bits.

Our fasteners are suitable for use in aluminium, steel and various other metals.

They are particularly suitable for the following industries: Ventilation and air conditioning technology, automotive, mechanical engineering, medical technology, energy, household technology, metalworking and many other industries that use thin sheet metals or thin-walled components.

Information and more

Downloads

Are you interested in QUICK FLOW® Plus thin sheet fasteners? You can download further information here.

Thread-grooving fasteners for metal

Application examples of QUICK FLOW® Plus screw

Take a look at some practical examples of Böllhoff’s QUICK FLOW® Plus thin sheet fasteners in action.

WE ARE HAPPY TO HELP

Do you have any questions or a current project?

Let us know – we will get in touch with you.

Contact us