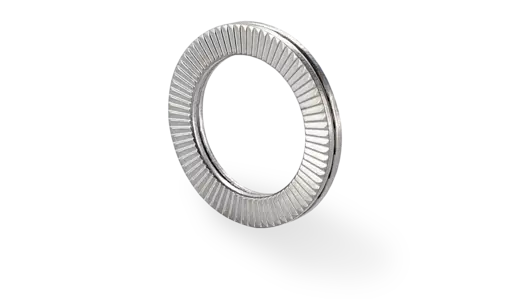

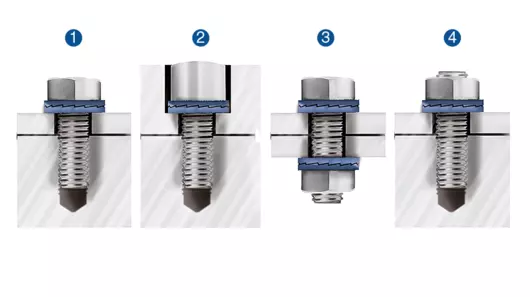

The Twin-Lock standard design is suitable for a wide range of applications – including countersunk bolts. The lock washers are available in a wide range of materials and coatings.

Materials

- Tempered carbon steel, hardness 465-550 HV10

- Stainless steel AISI 316 in accordance with EN 10088 – 1.4404, surface hardness ≥ 550 HV0.05 after surface hardening (Kolsterising®)

Surface coating for carbon steel

- Delta Protekt® KL100 + VH301 GZ, Cr6-free, corrosion resistance min. 600 hours (salt spray test in accordance with ISO 9227)