Products

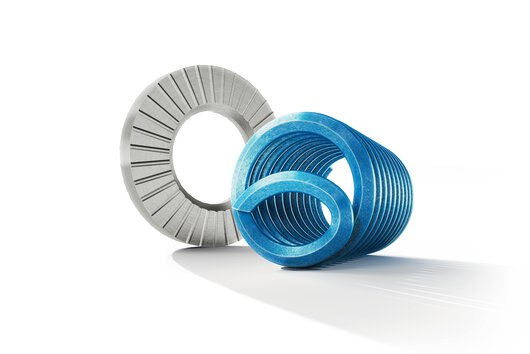

Small parts, big effect – our portfolio

Whatever components you want to join together, we can offer you the right solution.

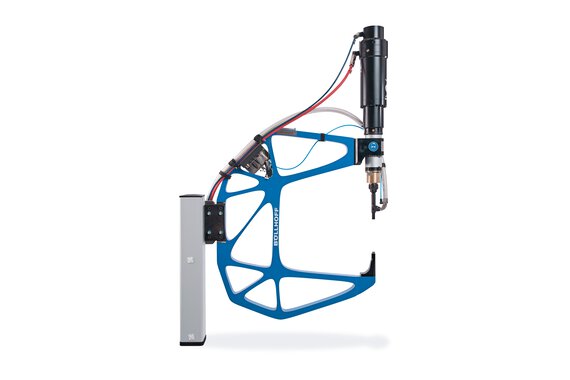

360° joining technology – everything from a single source

Whether standard parts, custom-made drawing parts or special fasteners: With our broad product portfolio, we always create precisely fitting connections. For every industry and for every application. We think holistically – and also support you with assembly and logistics solutions in the sense of our 360° joining technology.