Success stories

Klaas Alu-Kranbau GmbH

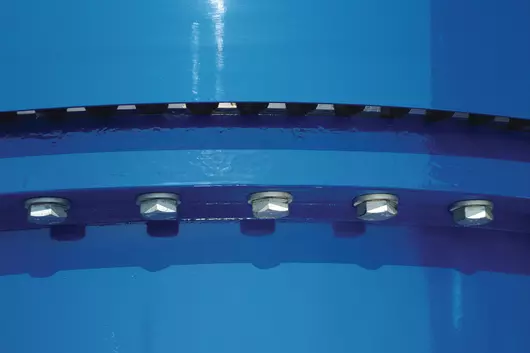

RIPP LOCK® self-locking washers for effective screw locking on truck cranes.

For dynamic connections

RIPP LOCK® self-locking washers effectively prevent threaded fasteners from working loose under dynamic loads. When dynamic loads come into play, the bolted connections must meet very specific requirements. We found an effective, cost-efficient way to help Klaas optimise the connections on the slew ring of a crane.

Initial situation

Screw connection with optimisation options

Ever since it developed the first aluminium crane, Klaas has made a name for itself as an innovative engineering company in Germany and beyond. Roofing contractors, furniture removers and fire services around the world rely on its sophisticated and lightweight cranes.

Our job was to optimise the bolted connections on the slew ring of a truck crane. As the fasteners are subject to high dynamic loads, 2 x d length spacer sleeves were originally used. Our aim was to make these spacer sleeves redundant. We also wanted to address the fact that the outdated coated steel fasteners that were being used were susceptible to corrosion.

Solution

RIPP LOCK® self-locking washers for the truck crane's slew ring

RIPP LOCK® rendered the spacer sleeves that had been used up until then redundant. As the intermediate element between the connecting part and the fastener head, screw locks regulate the friction factor and maintain the necessary pre-tensioning force, even under high dynamic loads.

RIPP LOCK® washers, screws and nuts are mechanical locking elements which are proven to prevent fasteners from working loose. This reliable locking effect is achieved by radial ribs which press into the material when the element is fastened.

The high-quality zinc flake coating on the RIPP LOCK® self-locking washers and on the hexagon head bolts and nuts provides effective corrosion protection. Salt spray tests confirmed resistance to red rust for 480 hours.

Result

Optimising components to reduce costs

The fastener stays in place. The mechanical unscrew lock provided by the RIPP LOCK® self-locking washer prevents the screw connection from working loose under dynamic load. When fitted with this corrosion-resistant, heat-resistant locking element, the crane's slew ring is capable of withstanding even extreme dynamic loads.

The RIPP LOCK® self-locking washer combines many of the individual advantages of previous locking elements. As a general-purpose product – the relatively large outside diameter complies with DIN 125 and ISO 7089 – it can be used almost anywhere. Easy installation and removal means that the product can also be used more than once. By eliminating the need for spacer sleeves, we have been able to streamline Klaas's range of C-parts. As a result, the solution offers not only technical, but also economic benefits, so our customer is doubly delighted.

Customer benefits

- Highly effective anti-rotation lock

- Corrosion protection

- Outstanding wear resistance

- Improved quality

- Reduced costs