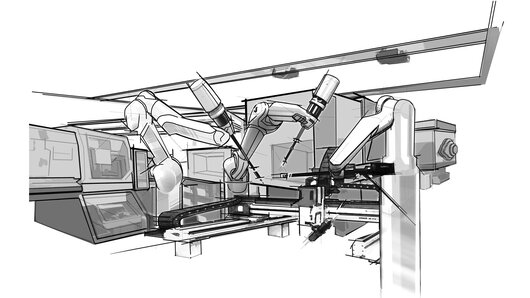

The machine frame is an important component in mechanical engineering as it forms the basis for the entire machine and supports the various components such as drives, machine tools and control units. The machine frame must therefore be extremely rigid and durable to ensure precise and reliable processing of the workpieces. The choice of fasteners depends on various factors, such as the load, the environment and the types of components to be connected.

We can provide you with the right solution for every requirement.