Features

- Compact design for ideal joining point accessibility

- Spiral feed magazines store up to 47 tacks

- Limit position and position sensing

- Real-time data processing

- RFID chip to store all tool and process-relevant parameters

Joining at high speed

Universal material combinations are becoming increasingly important, especially in the development of modern vehicle and car body designs. RIVTAC® is particularly suitable for joining aluminium, steel, plastics and non-ferrous metals as well as for mixed joints, multilayer joints and hybrid joints of these materials.

Plus factors

Joining without pre-punching with access from one side only.

Flexible application for mixed joints, multilayer joints and hybrid joints.

Reduction of joining and cycle times to a minimum.

Method and principle

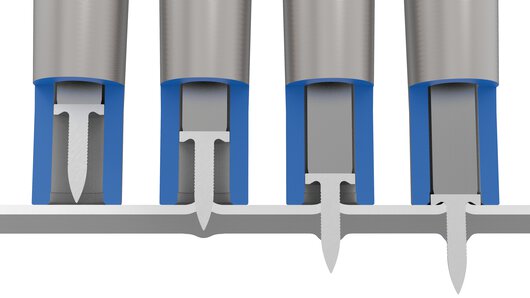

This innovative mechanical joining process utilises a tack – a nail-like auxiliary joining part, that is accelerated to a high speed and driven into the non-pre-punched parts. The ogival point of the tack displaces material. The speed, which can be controlled by means of the adjustable joining pressure, is dependent on the materials and component thicknesses. Due to the short-term increase in temperature in the joining zone, the parent material flows into the annular grooves on the shank of the tack. This achieves a high degree of form fit for the joined parts. The pressing and compression of the material – especially in the case of high-strength steel materials – results in a non-positive joint. An important condition for this method is sufficient stiffness of the joining parts so that they can resist the penetration impulse of the tack without major deformation.

We are happy to help

Let us know – we will get in touch with you

Contact usInformation and more

Are you interested in RIVTAC® Automation? Please download further information here.

ANY QUESTIONS?

Want to know more about our products or services? Our team will be happy to advise you.

Contact us